Clover

Valley Lumber Co. #4

2011 Restoration

Work

Log

(Click for archived 2010 2009 and 2008/7 logs.)

(Click for archived 2010 2009 and 2008/7 logs.)

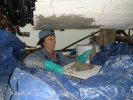

Jeff tightening piping in the cab. A lot of work is happening on the engineer's side. Gerald insulating, Pam climbing back up with another bucket of mud and Henry in the cab doing some fabrication work. |

Henry working on PLA's large sheet metal brake that will be used to fabricate the new jacket. Gerald still hard at work, this time on the fireman's front door. |

Gerald installing the last few pieces of insulation. Pam "mudding" the belly insulation, a fun job as a good portion of the mud falls back down on you. Pam is still smiling through it all. |

Scott covering the calcium silicate insulation with a fiber / cement mix in preparation for the jacketing to be installed. | ||

CJ and Gerald working on boiler insulation. Henry and CJ (the other one!) working on the sheet metal brake in preparation for the jacketing work. | ||

Gerald at work insulating the firemans side. Notice the buttstrap that will be insulated later with thinner material. Top of the first course with insulation around the bell, dynamo bases and the buttstrap insulated with a thin layer of calcium silicate. The rivet heads are not insulated. |

Master Insulator Pam at work on the 3rd coarse - almost 3/4 of the way done with insulating. Tom wire brushing one of the better looking pieces of material in a futile attempt to save some of the original material. In the end, we decided that it is only good for a pattern. |

|||

Henry welding in additional cab floor supports to try to fix the "sagging cab floor" issue. Number 999 of 1001 uses for a broom. Gerald cleaning rust off a piece of the old jacket material. |

|||

Jeff looking though the old jacket material to see if any can be saved. The sheet metal has done its job over the last 90 years but is severely corroded and needs to be replace. CJ under the engine installing insulation. |

|||

Alan driving the Pettibone with another piece ready to go back on the #4. This time, it's the dynamo. Gerald positioning the dynamo to install the mounting bolts. |

|||

The Mallet outside waiting for more parts in the early morning mist which seemed more like another day of rain. This is July, correct? Gerald, Tom and Jeff mounting the bell yoke back on the boiler. |

|||

Jim doing a little painting on the sand dome. Pam and Jeff place the sand dome back on the boiler in preparation for insulation. |

|||

Why does it seem that Pam is always found under the locomotive? Probably because it requires someone smaller and Charlie is out of town. As before, Jim is busy custom cutting the blocks for Pam to install. |

|||

Alan is busy installing wrapping around the lubricator lines. The wrapping will keep the lines from abrading against the boiler shell. |

|||

There is always something else to work on. This time, it is the sand dome. The base is rebuilt and ready to go back on. Gerold is expressing is delight at lagging a boiler on this bright, sunny day. |

|||

CJ working on the upper portion of coarse #2. Nearly half done! Les and Chris installing new air piping between the new air tanks. |

|||

Pam insulating the belly of the beast. Pam and Jim at work. |

|||

Master carpenter Henry trying his cutting skills on calcium silicate insulation instead of lumber. |

|||

Dave and Gerald running wire around the boiler which will hold the block insulation during installation. Pam setting block insulation near the top of the boiler. The first coarse is almost done, 3 more to go. |

|||

Henry making some "fine" adjustments in preparation for some piping repair. Gerald and Henry tightening up a leaky injector line pipe. |

|||

We now have a reinstalled and properly working coupler. |

|||

Johnathon at work prepping bolts for reinstallation of the rear coupler pocket. The pocket is not original to this engine. When Clover Valley installed it, they did a really poor job. Johnathon tightening the pocket mounting bolts. |

|||

Always look out for flying brick when brickwork is in progress. |

|||

Jeff Waiting with the masonry saw, ready for the next brick to cut. The keyhole firebox on the #4 required a lot of brick cutting and fitting. Gerald setting the flash wall brick. |

|||

Henry and Gerald working on piping in one of the many tight spaces on the #4. |

|||

Not a lot of progress on the brickwork but it looks like everything is ready to go - just need someone to fill those gloves and start working. Dave discovers the reason for the lack of progress - Gerald has not had enough coffee yet. |

|||

Gerald and Alan take a break from bricking. It was a rainy day outside but they missed the bad weather, spending 5 hours inside the confines of the firebox. Mixing another bucket of firebrick mortar. |

|||

A good steam test today on the Clover Valley #4. We found a few things we need to fix such as valves that need to be relapped, some leaky flexible caps that did not leak under a hydro and leaky piping but overall we were all smiles after the day. Thank goodness this hurdle is over, on to finishing the locomotive to put her back in service. |

|||

Jeff's thumbs up says it all. |

|||

Pam insulating the air compressor steam feed line. Test fitting the new builders plates donated by George Lavacot. They will look great once we permanently mount them. |

|||

Jeff showing Gerald how to lap the throttle. One scary group of volunteers! |

|||

Errol taking it easy on a "comfortable" folding chair while supervising. It is good to have him back , we have missed him. Jeff (who volunteers at the Orange Empire Railway Museum) spending a few hours of his northern California visit. |

|||

A bunch of help involved in mounting the air tank on the engineer's side. Pam, Henry (on the lift), Scott and Chris. A group volunteer photo for April 9th. Henry, Jeff, Scott, Chris, Alan and Pam behind the camera. |

|||

Front end work with Scott and Jeff. Pam painting the piping in the cab. |

|||

Final picture of the newly repaired smokebox, new petticoat and blower ring before the smokebox front is installed. Pam and Scott preparing the front end for the smokebox front to be installed. |

|||

Pam and Scott guide the front end into place. Jeff watches while Chris and Scott muscle the front end. |

|||

Henry tightening his new air tank bracket built for the fireman's side air tank. The new bracket is mounted off of a cab support rather than from the cab floor which cause it to sag. Completed and painted front end. |

|||

Charlie was caught dressing up the superheater plate. |

|||

Finally, the new blower ring and petticoat were installed. |

|||

While Alan was busy getting his hand stuck in the #4's throttle, Henry fabricates a new air tank bracket. |

|||

Charlie, Gerald and CJ reinstalling the power reverse. Considering the difficulty we had taking it off the #4, this was a welcome easy job and the bolts almost slid into place. |

|||

Number 4 basking in the February sun. |

|||

Dave doing some final cleanup on the power revers guides. Scott, Gerald and Charlie rigging up the power reverse. |

|||

A couple wees work by Henry, Jeff, Joe, Jim and others resulted in a rebuilt petticoat and new adjusting brackets. Jim and Henry mounting the petticoat in the smokebox. |

|||

Our blacksmith Joe Mann made new adjusting brackets for the petticoat. The old ones were welded into the smokebox and adjustment was impossible. |

|||

There is no better way to force work to be completed than locking Alan in the firebox until he finishes the Form 4 Documentation. |

|||

C.J. and Johnathon making a new air gauge support. Charlie changing the brake valve on our SP boxcar in preparation for the March 13th Photographers Special. |

|||

Scott cleans and paints the air pump bracket. Charlie and Jim finish painting the power reverse. In the background, Henry and Jeff work on making new brackets for the petticoat. |

|||

Another project completed - the superheaters all reinstalled and tightened. |

|||

Gerald and Pam work on cleaning all the caked grease and grime off the power reverse. Chris and Les working on piping in the cab. |

|||

We removed the old air pump plumbing from th top of the smokebox and were able to get the last row of superheater elements installed. |

|||

The backhead shelf was painted and then installed in addition to finishing the piping for the whistle. |

|||

Jim, Pam and Henry working on the superheater units. Dave Loyola inside the smokebox installing additional sealer around the branch pipe packing. |

|||

Henry carefully applies a new superheater clamp to the tube bundle to replace one of the old burned and rested clamps. A newly installed clamp ready for welding. |

|||

Henry welds the clamp together. Alan and Errol tightening up the first row of superheater units. |

|||

Pam lapping the superheater ball joints which fit into the header. A tight lapped metal to metal joint is necessary on all 36 joints to prevent steam from leaking into the smokebox. C.J., Scott and Charlie in the smokebox muscle a 15' superheater unit into the smokebox. |

|||

Jeff "The Inspector" is on site in the smokebox to check Charlie's work. Charlie Lapping the superheater header in preparation for superheater installation. |

|||

Henry and Jeff installing the flexible exhaust joint from the low pressure cylinders to the nozzle in the smokebox., Pam, Jeff and Henry (hidden in the background) finishing the nozzle installation. |

|||

Henry with the reassembled spring and snap ring positioned in the press. Johnathon thinks he can provide help with that dinkey sledge when we are using a 50 ton press. Maybe he should get a bigger hammer!! |

|||

Gerald working rebuilding the injector for the engineer's side of the locomotive. The cleaned underside of the nozzle. The spring pack fits against the inner flat surface and the exhaust pipe seals into the center hole that leads to the nozzle. |

|||

The spring pack after about 4 hours of Henry cleaning the nozzle casting to get the pack out. Pam making new gaskets. It sure would be easier if we could just purchase them. |

|||

Scott Martel removing the brake cylinder lids in preparation for installing new brake cups. Another one of the locations that are difficult to get to on compact locomotives. Chris and Les working on the brake stand plumbing in the cab. |

|||

Henry starts cleaning the interior of the exhaust nozzle / flexible steam pipe joint. Pam cleaning the exhaust pipe between the smokebox and front cylinders. Not a great place to work at all. |

|||

Henry starts cleaning the interior of the exhaust nozzle / flexible steam pipe joint. |